Custom Plastic Injection Molding can often be a more cost-effective manufacturing process for high volume parts when compared to other manufacturing processes. Plastic parts are created by injecting molten plastic into a specifically designed mold. This provides our customers with control and maximum design flexibility over the end component, including the ability to choose from a variety of plastics. Also, this allows for the opportunity to supplement with additional material to get the exact characteristics you are looking for in your plastic materials.

Some resin choices can provide different engineering characteristics compared to bar or plate stock, which gives you the ability to better suit your application. Often the part requirements need to consider different material properties such as density, elasticity, color, and other mechanical properties. Over-molding is an additional option that can provide you with a final product made of different materials or colors which adds even more customization to your plastic injection molded parts.

Our experts can help you analyze which material will work best for you and improve your design for manufacturability. Common materials include ABS, HDPE, Nylon, PP, Filled Resins.

Do you have the need for a precision part with a complex design? No problem! The various tooling and plastic injection molding process allows for a variety of different component configuration options to meet your specification. Additionally, the materials used are lightweight, durable, high-strength and cost effective compared to many other materials.

Also, staying in line with our sustainability and waste reduction initiatives, plastic can be easily recycled using only as much plastic as necessary to produce each part and ultimately reducing waste which benefits our environment.

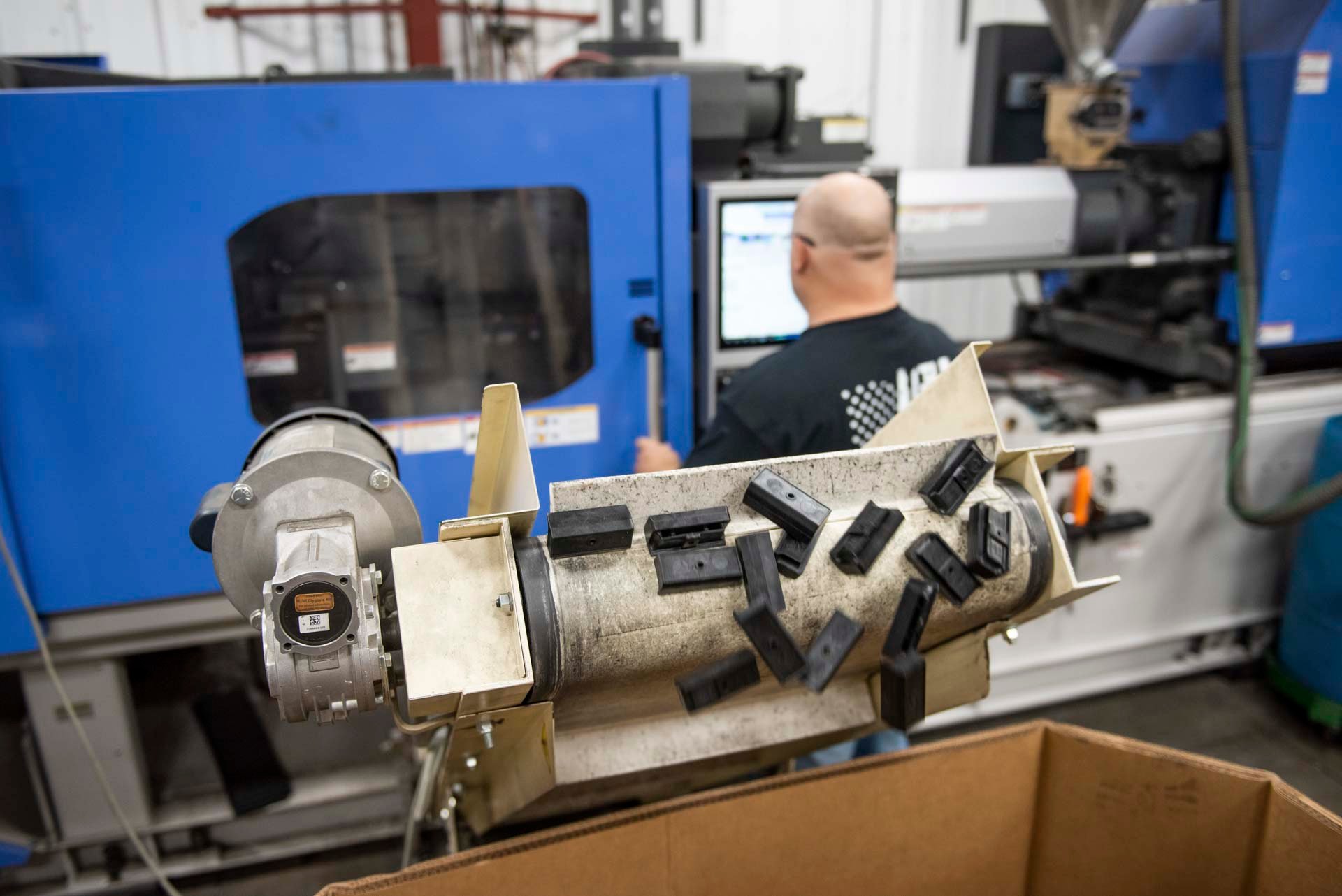

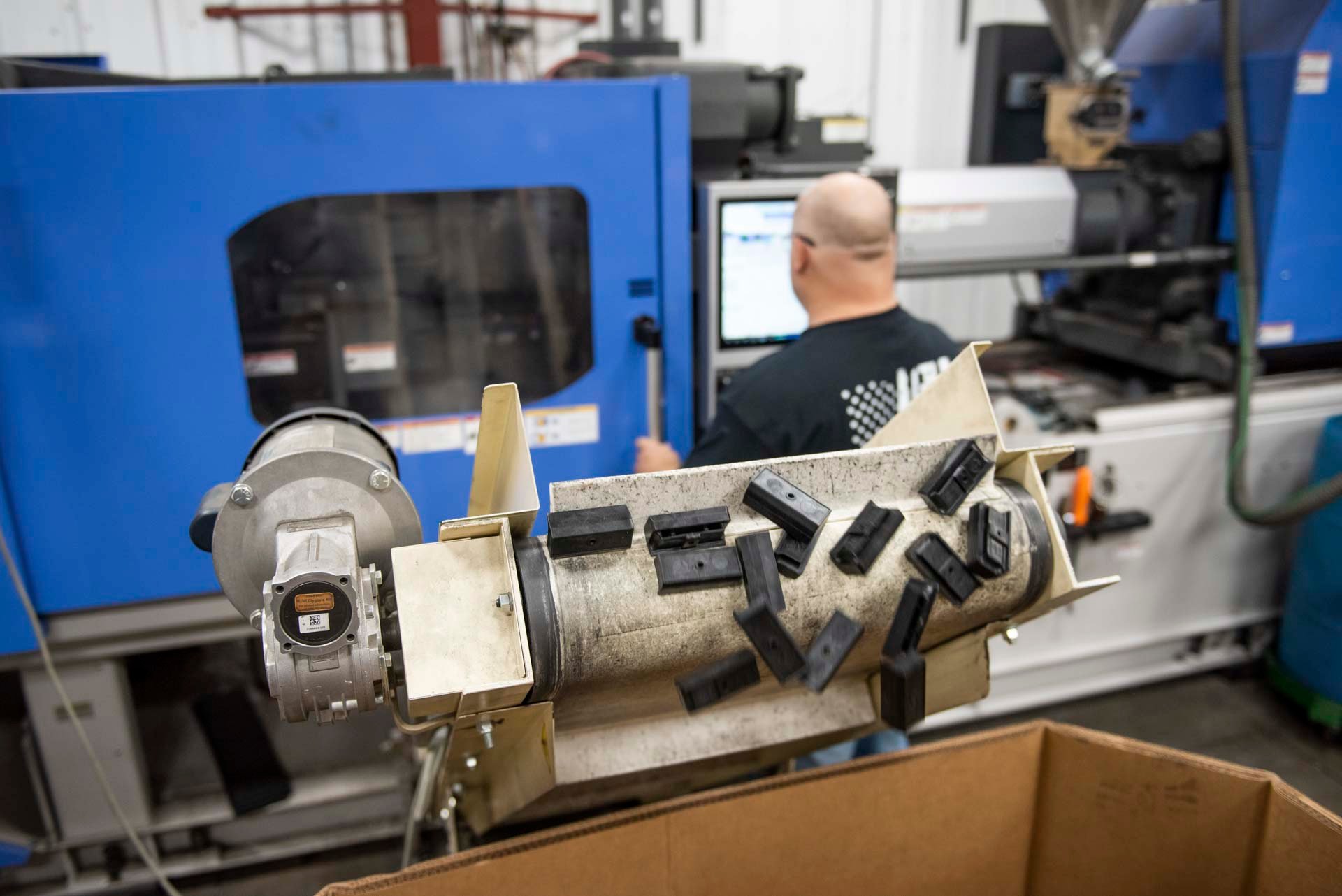

Like most manufacturing processes, our injection molding services start with prototyping using our CAD drafting services. We then build the tooling as required, test the tooling, provide sample parts if necessary and make any required adjustments.

As mentioned above, our experts can assist you in analyzing your process to determine the best materials to use for your final production part. For example, part weight can be reduced with injection molding versus machining from solid material by implementing gussets and ribs for strength instead of using a solid block.

When working with Plas-Tech, you will have a worry-free experience that reduces your efforts by having us manage the tooling. We build all of our tools in-house and we can test/maintain them during a production run. If there is a need for changes, we can make almost immediate modifications to molds with our in–house tooling department.

When it comes to trimming and packaging, we can package molded parts per customer specifications and we can build molds that will remove the gate when the tool opens during the molding cycle to better separate waste from good products.

Finally, we can match colors and will perform a test run for your color approval. We offer the flexibility to change material, color and/or finishes while still providing you with short lead times and high-quality parts.

We can do production runs of parts from 50 to 1,000,000 pieces and beyond. We can use one of our in-house injection presses with capacity of up to 300-ton and a shot size of 32 ounces or a 500 ton with a 60-ounce shot readily available from our molding partner. Additional capabilities include the ability to run molds that require hand load cores or over-molding.

We have the ability to run 24/7 and can meet your delivery needs with lead times as short as 2 weeks. If you require parts faster, we offer the convenience of stocking programs.

Call our experts today and learn how working with a premier custom plastic injection molding services company will make your life easier and save you time and money!

So, in addition to our plastic injection molding services we offer:

Additionally, we can leverage our industry connections to help you get a completed part or assembly without the hassle of managing it all.

Call our experts today and learn how working with a premier molding company will make your life easier and save you time and money!

Injection Molding

Injection Molding  Injection Molding

Injection Molding Plas-Tech Tooling is a dedicated to providing high quality manufacturing solutions to customers across a wide range of industries. We strive to partner with our customers to provide the best possible solutions.

If you have any questions or need help, feel free to contact us.

Mon – Thurs 7am – 4:30pm, Fri 7am – 12pm

© Plas-Tech Tooling 2025. All Rights Reserved. Privacy Policy Terms & Conditions

Website Designed by Running Robots