Once you have decided that plastic injection molding is the right process for your application and have selected the materials for your final part, one of the most critical parts of our process is creating the plastic injection molding tooling. By taking the specifications provided from the part designer, the tool designer will ensure the end product is moldable. Once confirmed, we can design the tools needed for the job. At that time, we will review the entire production process to ensure this is the most cost-effective way to make your part.

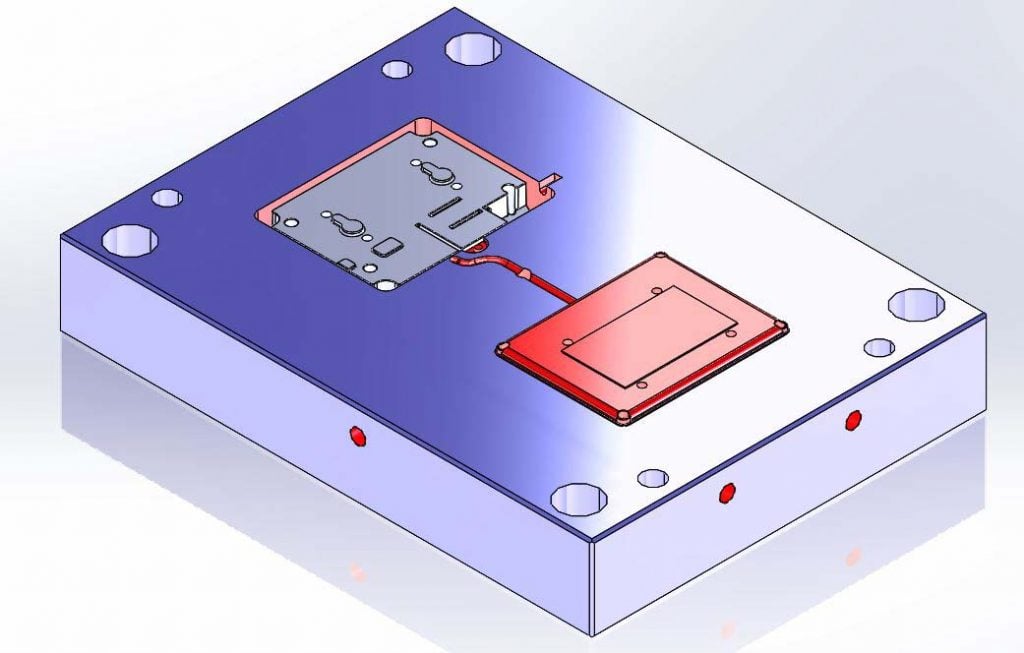

The mold is a hollow metal block of a specific fixed shape formed by the core and cavity in which the molten plastic material is injected during the manufacturing process. This is often a highly technical, complex process that requires a great degree of precision to produce top quality parts with tight dimensions.

When designing plastic injection mold tooling, some of the first terms you may hear about are the mold core and mold cavity. The cavity is the inverse geometry of the outside portion of the final part whereas a core is what will form the inside portion of your part. Determinations must be made in terms of the number of cavities required as well as gating locations (fill points).

Other tooling components include adaptor plates, spacer blocks, location rings, ejector plates and ejector pins. Part of the process also involves drilling many holes into the block which allows for temperature control during cycle times using hot water, oil or heaters. The various components of the overall mold are referred to as tooling.

The mold can be made from different materials including steel or aluminum. Often aluminum molds are faster to make and are great for initial production runs or low volume parts, but they may not have long-term durability. Steel molds on the other hand, are usually best for high volume applications or in situations where the plastic material being injected into them is more abrasive.

Our staff of expert tool and die makers will ensure you get your parts as quickly and cost effectively as possible. This eliminates the need to send tooling to other outside locations. Furthermore, we can test the tooling in-house, provide fast turnaround on changes, make any adjustments that may be necessary and ultimately ensure the quality of the end product.

We offer great flexibility to our customers. We can create tools to run either in our presses or yours. Our experience allows us to:

Our capabilities include making modifications and repairs, which helps our customers through the life cycle of the tool. We can also provide maintenance of tooling that is built and molded in-house up to a predetermined volume. Finally, we can arrange test runs and verify the mold integrity before a production run to verify parts are exactly what you want, saving you time and avoiding costly delays.

On our plastic injection molding page we call out the benefits of injection molding, but often the one drawback is the high upfront cost of molds which includes the associated tooling. At the beginning of a project, we will discuss things like your budget which includes targeted fixed and variable costs with respect to the parts being molded.

We offer a variety of payment options to fit any type of customer including:

Call us today to learn how our plastic injection molding tooling experts can walk you through the tooling process saving you time and money!

Plas-Tech Tooling is a dedicated to providing high quality manufacturing solutions to customers across a wide range of industries. We strive to partner with our customers to provide the best possible solutions.

If you have any questions or need help, feel free to contact us.

Mon – Thurs 7am – 4:30pm, Fri 7am – 12pm

© Plas-Tech Tooling 2025. All Rights Reserved. Privacy Policy Terms & Conditions

Website Designed by Running Robots