Quality Assurance

Learn More

Quality Assurance

We provide only the highest of quality.

Regardless of all the services, CNC machinery, machining processes, or even customer service a supplier offers, in the end you must receive a product that is of high-quality and meets your quality standards and specifications. Plas-Tech Tooling has an on-site Quality Assurance (QA) team that will ensure your parts are the desired shape and built to spec.

We have a fully stocked QA lab with all the gauges and measuring devices needed to ensure we get it right for you. This includes a portable coordinate measuring machine (CMM) allowing us to verify the geometry of each part regardless of the complexity.

Additionally, we can provide Initial Sampling Inspection Reports (ISIR) or Production Part Approval Process (PAPP), First Articles, Material Certs, and Restriction of Hazardous Substances (RoHS) certifications. In short, we have the experience that will ensure you receive high-quality components while providing any required document.

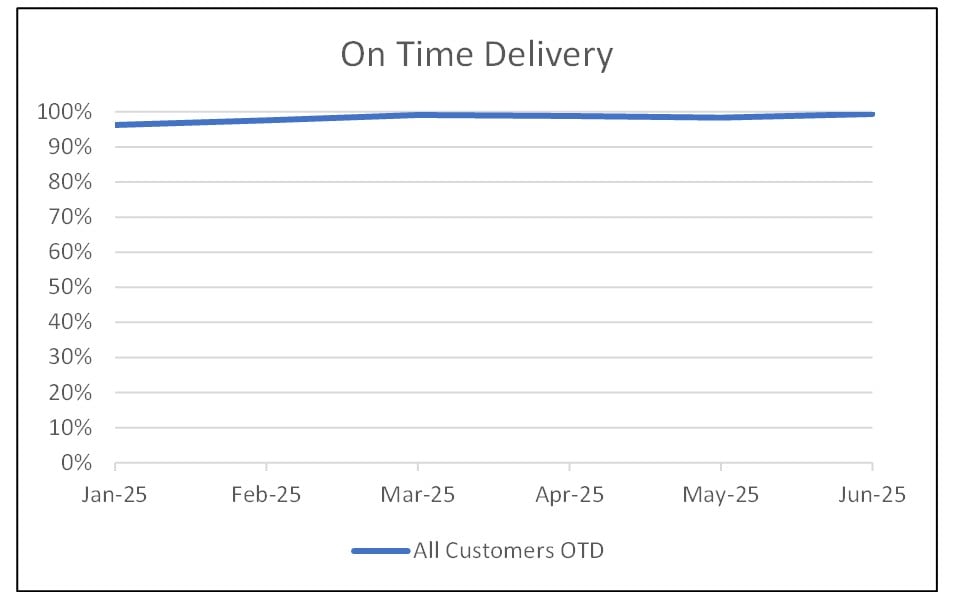

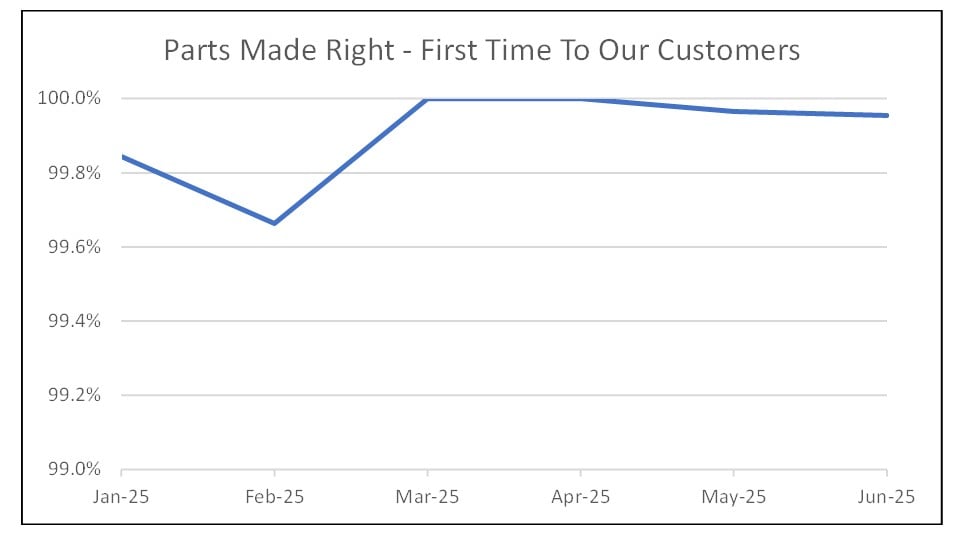

Check out our quality record below.

On Time Delivery

Right First Time

ISO 9001:2015

We have been certified since 2020 and meet all applicable requirements of the ISO 9001:2015. The international standard specifies requirements for a quality management system (QMS). This certification ensures that there are well-defined processes and communication structures, tasks and set responsibilities throughout our entire organization.

Additional benefits include:

- Increased efficiency and productivity

- Cost-effective processes with less waste

- Data based approaches to decision making

- Effective record keeping

- Consistent outcomes

- Continuous improvement

Overall, our certification gives you the level of service you want from a CNC Machining and Plastic Injection Molding supplier. You can view our certificate here.

Our Quality Process

Our Quality Policy Statement:

“Plas-Tech Tooling, Inc is dedicated to meeting customer expectations and all other requirements by maintaining a quality management system that emphasizes continuous improvement.”

Plas-Tech Tooling, Inc.’s quality management system (QMS) objectives are:

- 100% on time delivery

- 100% right first-time components

- 100% customer satisfaction

We will work with our customers to understand their quality requirements from the start. Our process can include as little or as much as 100% inspection of parts as per your requirements. In any given year we run over 1500 different part numbers and ship over 1,500,000 parts and have a QMS that is flexible enough to handle not only this diversity, but also follows a process approach that meets the part’s quality standards and the requirements of ISO 9001. This system is also the baseline for our continuous improvement initiatives.

Call our experts today and learn how working with a premier production machining and plastic injection molding company will make your life easier and save you time and money!