At Plas-Tech Tooling, we offer our customers the unique experience of working with a company that provides both production machining and plastic injection molding. These capabilities give you plenty of flexibility when it comes to material selection for your manufacturing processes.

At Plas-Tech Tooling, we offer our customers the unique experience of working with a company that provides both production machining and plastic injection molding. These capabilities give you plenty of flexibility when it comes to material selection for your manufacturing processes.

We recognize you have a multitude of choices when it comes to selecting the right CNC machining supplier. Our customers are accustomed to relying on us to deliver small and high-volume metal or plastic parts that are critical to keeping their lines moving.

With the capabilities of a large machine shop and the flexibility, customer service and responsiveness of a small one, we work directly with our customers to provide creative, cost-effective and timely solutions to every project.

Our advanced machining capabilities along with our technical know-how, allows us to effectively manage complex projects of various sizes, weights, materials and surface finishes. We take great pride in our value-added services such as assembly, kitting, welding, inventory management, drafting services and more.

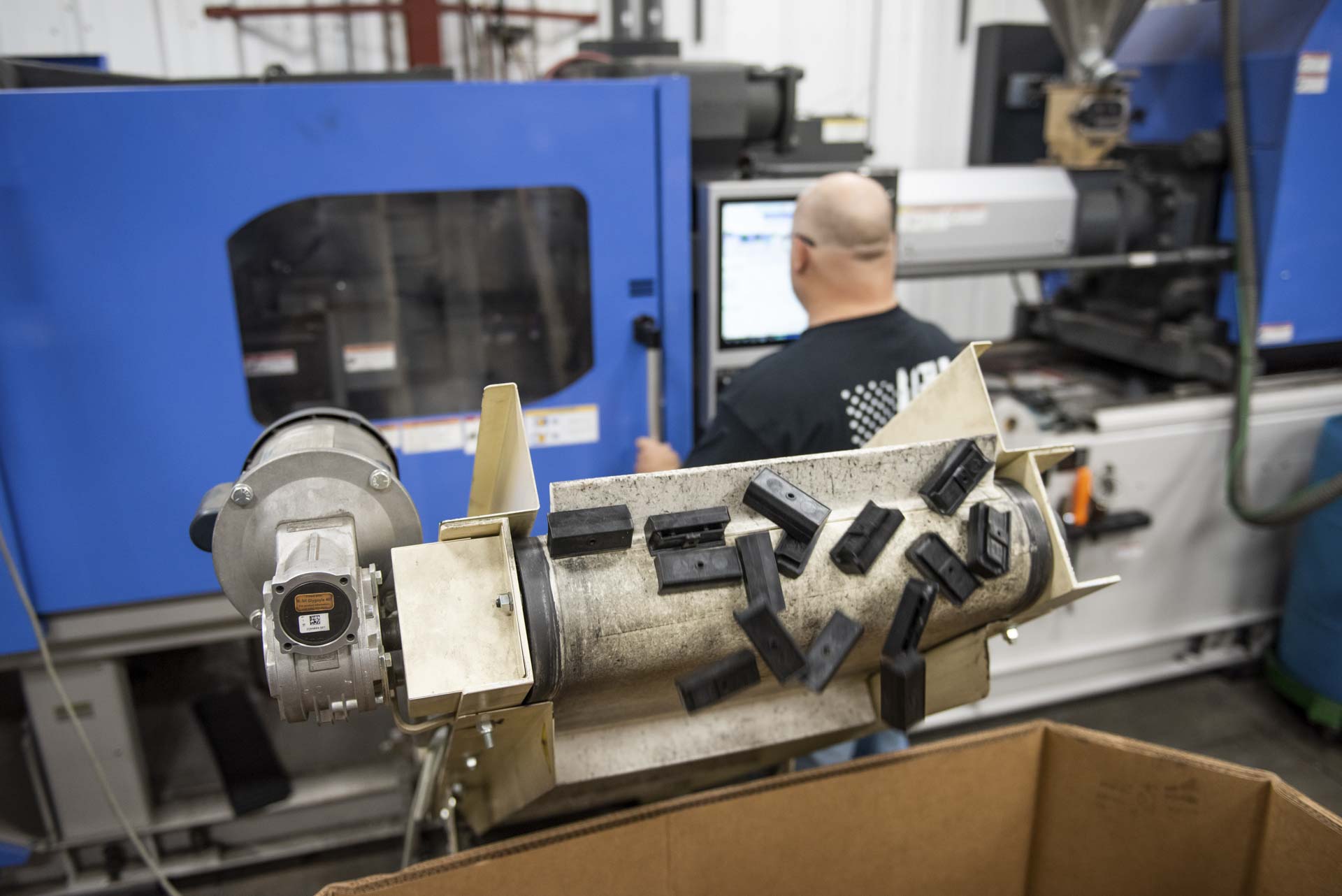

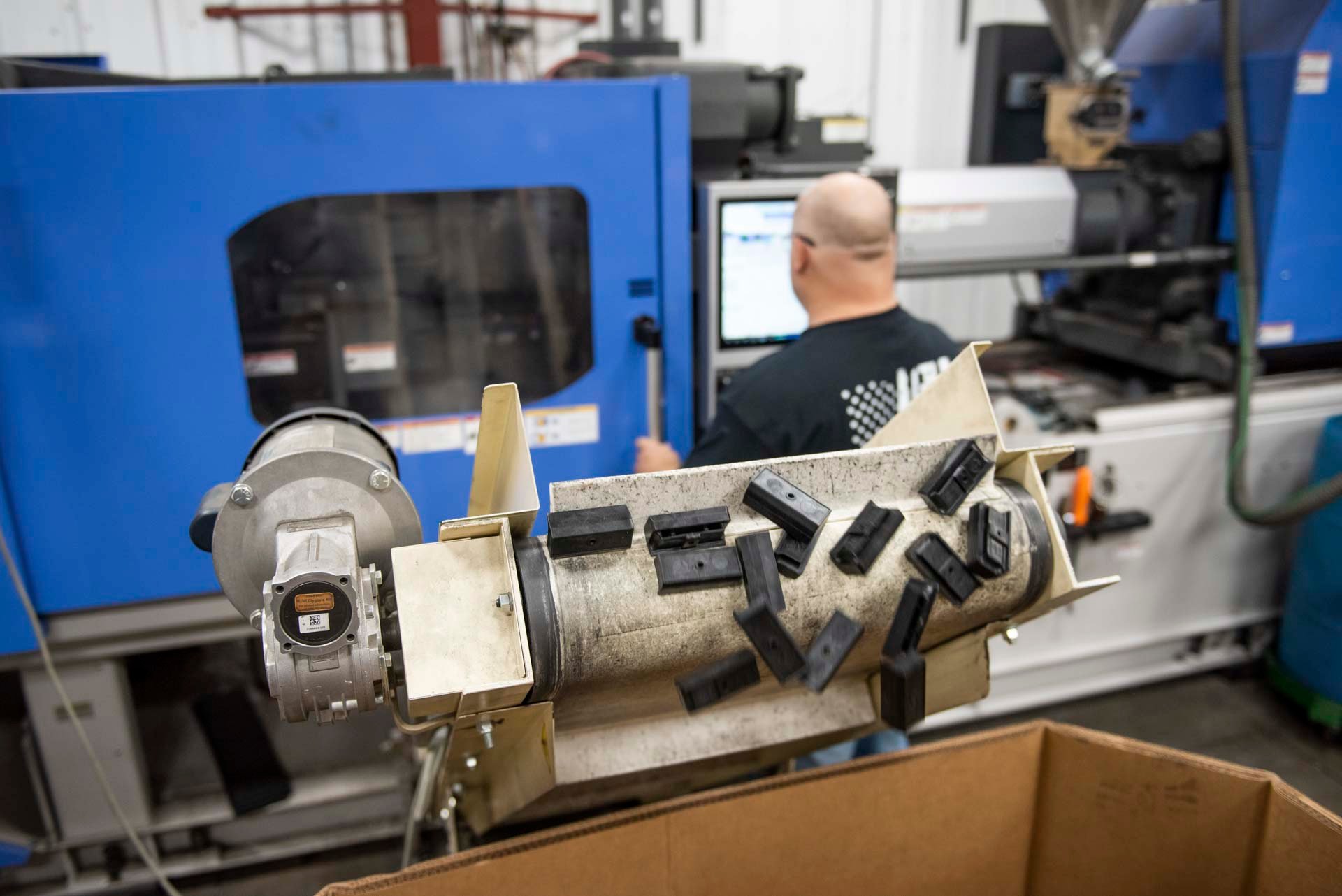

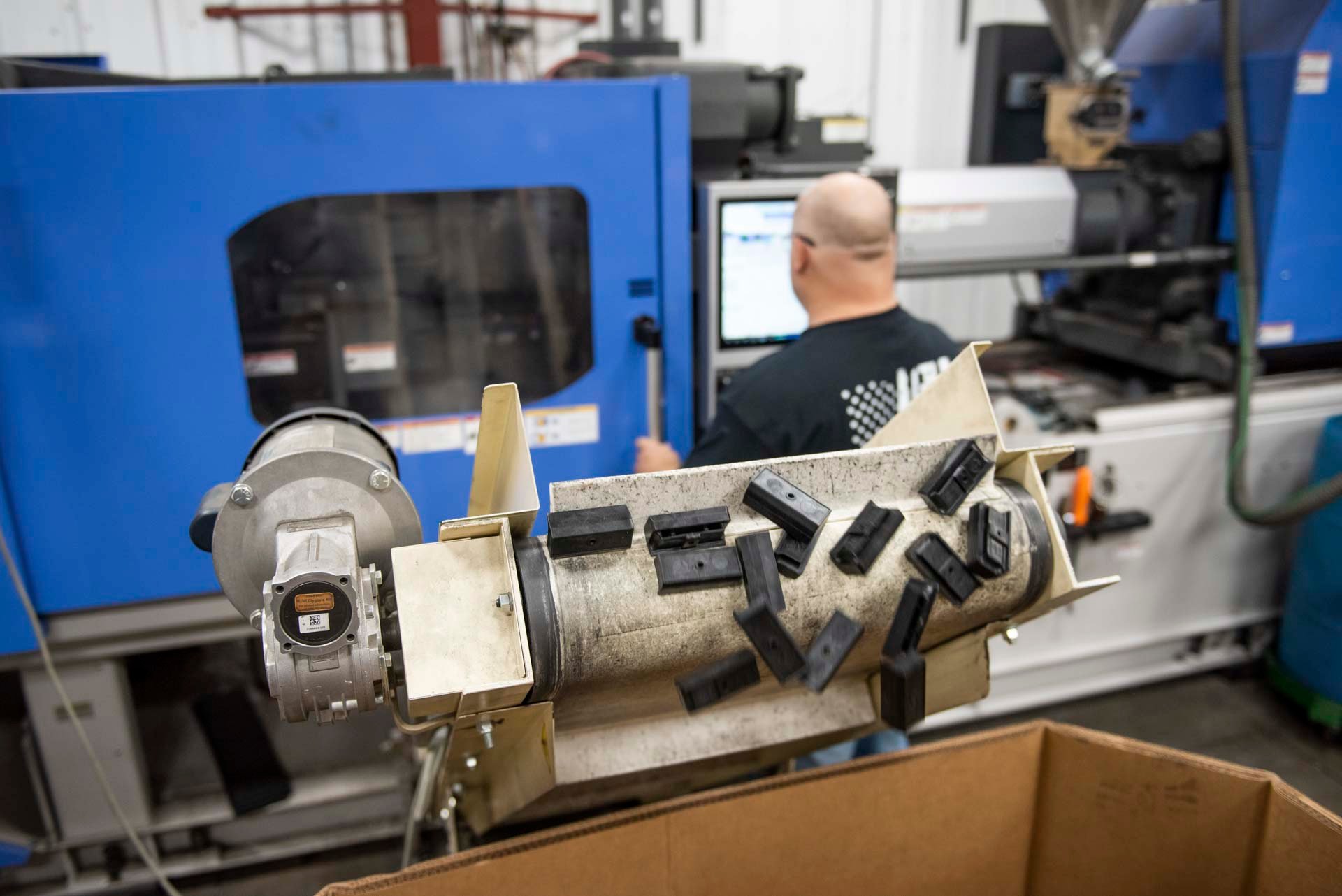

For plastic molded components, we give our customers a variety of molding options along with project control and design flexibility. We work closely with our customers to make decisions regarding material choice; weight, durability, strength, cost-effectiveness, or all of these. Finally, we will review the moldability of your part and provide you with design for manufacturability feedback to ensure your mold/molded parts are completed on time, within budget, and meet all other specifications.

Plas-Tech offers CAD Drafting services, or we can work directly from your print. We can design either simple or complex molds, test the tooling and even provide sample parts before a production run.

We are so much more than a machine shop offering small or large production runs. We listen and respond to your need for prototypes and emergency services, and can make transition to full production when the time is right. We are confident in the quality of our parts because the high-speed machinery provides you with components without compromising the dimensional stability of your parts.

Since 1993, we have been partnering with our customers to provide them with turnkey manufacturing solutions through production machining and plastic injection molding services. Our goal has always been to make their lives easier, saving them both time and money! Call us today!

When your equipment breaks down, we are here to get you back up and running quickly with our emergency machining services. We will work with your team to come up with a solution.

Demonstrated the ability to help customers overcome obstacles such as unrealistic due dates with multiple revisions while working with designers in several countries.

Added additional equipment and reduced non-value-added logistics.

Work with startups and provide a rapid response, prototyping and emergency machining services.

Machining

Machining  Injection Molding

Injection Molding  Machining

Machining  Machining

Machining  Injection Molding

Injection Molding From a single machined or injection molded part to an assembly or weldment requiring coatings and more, let Plas-Tech Tooling quote your project. We will find a solution that is right for you. No job is too big or too small.

— Fill out and submit the form with as much information as possible about the part and its application as possible.

— Plas-Tech will review the information and request more as needed. We will also provide any feedback that may help improve your part.

— Finally, we will provide a no obligation quote. Depending on the information provided and project complexity, quotes may be provided in as little as a few hours.

Please describe the project you would like quoted with as much information as possible. We will respond with a no obligation quote usually within 1-2 business days.

My wife and I started Plas-Tech in 1993 in a 2 stall garage and built our first building at our current location in 1996. Since that time, Plas-Tech has grown to 21.000 sq. feet and we have a great staff of 25 full and part-time employees. Building a business required long hours, hard work, and a determination to satisfy our customer’s needs by providing on-time, cost-effective machining services.

We continue to strive to develop a relationship with our customers that is based on mutual trust and a commitment to do the right thing in the right way. Our employees are involved in the process so they understand and are invested in the needs of our customers; taking pride in completing a project and having a satisfied customer as the end result.

Thank you for considering us for your manufacturing demands. Our goal is 100% on time delivery, 100% right first time components, and 100% customer satisfaction.

Founder

Plas-Tech Tooling is a dedicated to providing high quality manufacturing solutions to customers across a wide range of industries. We strive to partner with our customers to provide the best possible solutions.

If you have any questions or need help, feel free to contact us.

Mon – Thurs 7am – 4:30pm, Fri 7am – 12pm

© Plas-Tech Tooling 2025. All Rights Reserved. Privacy Policy Terms & Conditions

Website Designed by Running Robots